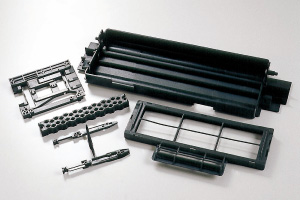

Molding Business Division

Supports a wide range of parts, from general purpose parts to functional parts, at low cost

Supports a wide range of applications, from general purpose parts to functional parts, using a variety of injection molding processes and cutting-edge technology characterized by a development and production system directly connected to future-oriented product markets for also developing metal parts produced using Metal Injection Molding (MIM), which is referred to as a 5th generation metal processing method.

Major manufacturing experiences

-

Chemical and medical equipment

- PSF, PES, PC

- Steam resistance, transparency, non-toxicity

-

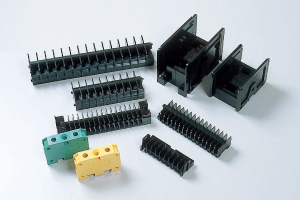

Electrical equipment

- PBT, PC, PPE, PPO

- Heat resistance, dimensional accuracy, electrical insulation, flame retardancy

-

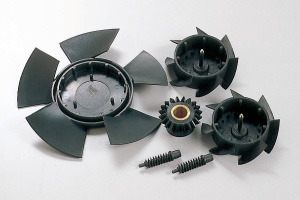

Precision equipment

- PPS, POM, PBT, PA66, PA46, CF reinforced products, GF reinforced products

- CF reinforced products, dimensional stability, mechanical strength, abrasion resistance

-

OA equipment

- ABS, GF reinforced ABS, GF reinforced PBT

- Flame retardancy, electrical insulating property

-

Special molded products

- Plastic magnets, PA

- magnetism, abrasion resistance, transparency

-

Metal powder injection molding

- SUS316L, SUS630, SU304, Ti

-

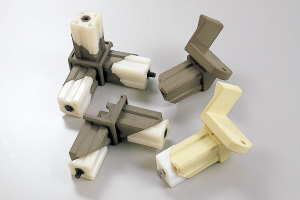

Metal substitution

- GF reinforced PA, POM

- Mechanical strength, weight reduction

-

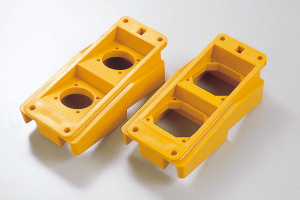

General industrial equipment

- ABS, UHMW, POM

- Sliding characteristics, abrasion resistance, oil resistance

-

Information equipment

- ABS, PC, PPE

- dimensional stability, Flame retardancy, formability